- Click on tac basics to view videos which explain the tac (a table-top automation center) and how it functions.

- Click on applications to see videos which demonstrate different ways in which tacs can be used.

First Step Automation LLC is a small business enterprise focused on the creation, fabricating , sales and rentals of tacs.

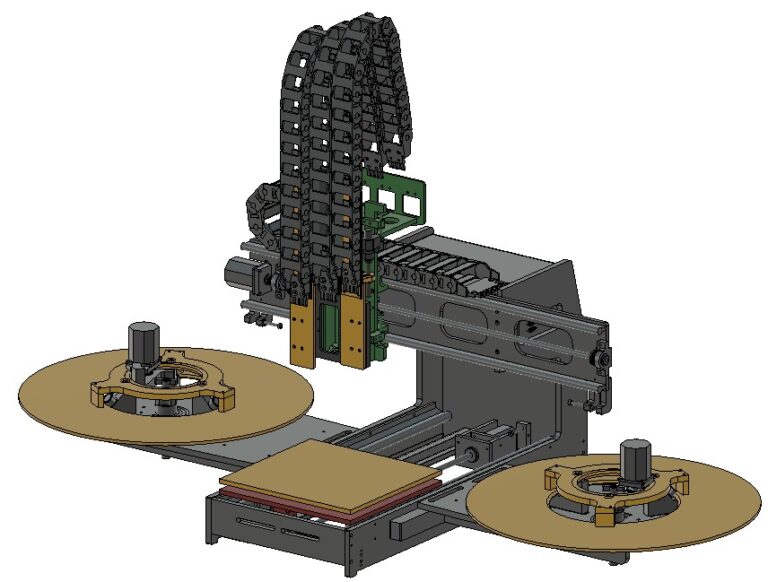

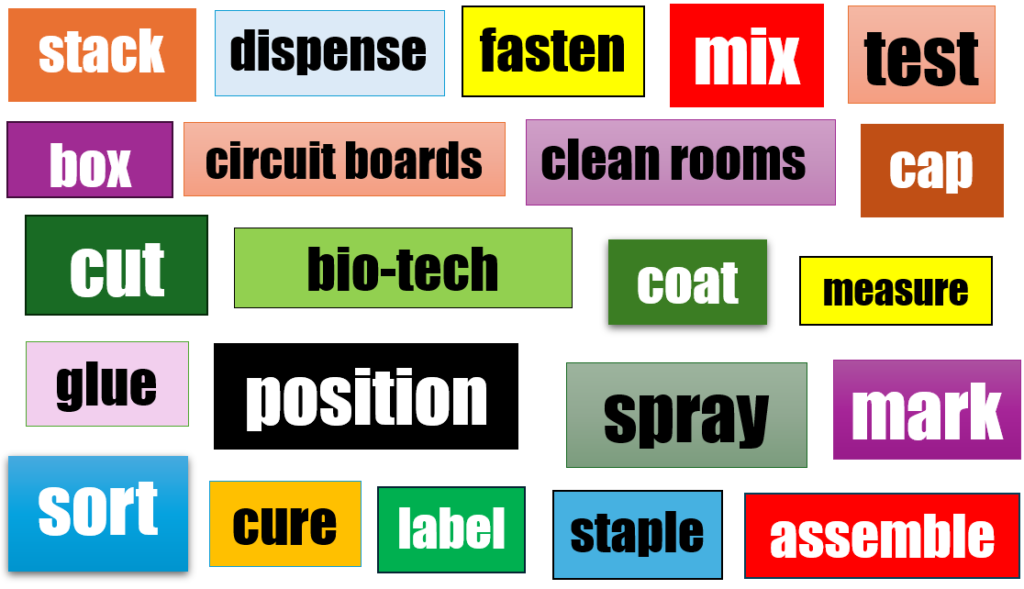

The tac (a table-top automation center) is a flexible, off-the-shelf, integrated automation platform designed for process or assembly applications involving small product items (a few cubic inches or less). The tac, patented by First Step Automation, (US 11,396,076 B2), is designed to be a reconfigurable, fully automatic, load, turn-on, and walk-away automation platform. Using commercially available application devices, tacs can operate as stand alone units, or as cells with other tacs or other equipment in new or existing automation set-ups.

Tacs are intended for low to mid volume production runs involving small to medium sized items:

- Tacs are envisioned for runs of hundreds or thousands of product items.

- Typically, any product items which can fit into a five inch cube would work well with a tac.

- But tac frames can easily be altered to accommodate taller or wider items.

A flexible, versatile, automation platform:

- It’d be hard to find anything more versatile.

- Tacs can make automation second nature.

- If you have one application suitable for a tac, then you’ll likely find more.

- Tacs can patch into or be added to existing automation lines.

- Obsolete systems can be salvaged by tacs.

- A tac can utilize one, two or zero rotary magazines. Up to four tacs can simultaneously share a common magazine.

- Magazines can employ either one or two discs (one above the other) – which can be moved in unison or individually.

- Customized nests or pallets can be used to position parts on the magazines and work table.

- Rotary magazines can be easily removed to allow a tac to work with other tacs or other equipment, such as conveyor belts, rotary tables, or process stations.

- Flexing cable carriers at the tac’s top keep electrical and feed lines from tangling.

- Tacs require no special electrical connections – it is a 120V 20 amp system.

- Tacs are shipped in boxes by package delivery companies as ready-to-assemble sections. Approximate weight of tac: 200 lbs., weight of shipping boxes, approximately 50 lbs. each.

- A typical stand-alone tac with two rotary magazines is approximately 70” wide, 42” high, 33” long. Something a standard industry table or cart can support.

Tacs Offer Low Risk:

- The tac is an off-the-shelf product; not one that is custom-designed and custom-built.

- Tacs can be bought or rented.

- If you’re renting one, you can box it up and send it back at any point… or get it ready for a different application.

- A tac can be out of the box, up and running in short order, as opposed to designing, fabricating, assembling, and integrating the components of a custom-built single use system.

- A tac can eliminate hours of integration work from many an application.

- Start small to get your process figured out. Then if you need more volume, bring in other tacs.

- It’s often easy to alter the layout of a tac application to accommodate the available floor space.

- Short on space? Mount a tac on a cart so it can be moved about and kept out of the way.

The tac is more of a steady work horse than a sprinter:

- Tacs can move right along running precise operations. But they’re designed more for continuous operation than for high speed activity.

- Set it up. Load the parts, and start it up. Then come back later to unload.

- Tacs are robust – not fragile. They’re built to hold up under use.

- They’re also suitable for clean room environments.

- They can be daily acid-washed per the requirements of the United States Food and Drug Administration. A tac won’t be damaged by the daily acid washings.

Easy upgrades can be made in the field with factory kits:

- To suit your needs, you can make your own changes to a tac… or you can order kits from First Step Automation to make typical alterations.

- For instance, to accommodate a specific application, a standard tac frame can be made longer or taller with pre-made sideplates.

- A single gantry tac can become a dual gantry tac. A forward gantry can be mounted on the frame to face the rear gantry.

- A single-disc rotary magazine can be converted into dual disc magazine by adding an upper disc.

- After you’ve converted a tac… you can later convert it back.

Who should be looking at tacs?

- Automation firms and system integrators that work with small product items should become familiar with tacs.

- Companies that are looking to get into automation.

- The question is, do you have an application involving small product items that requires automation?